Process Intensification

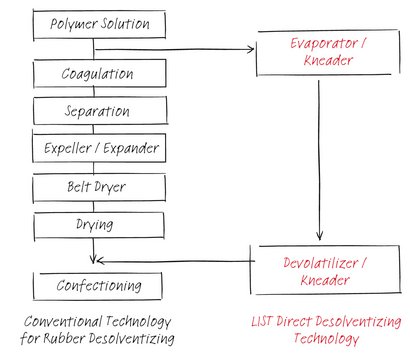

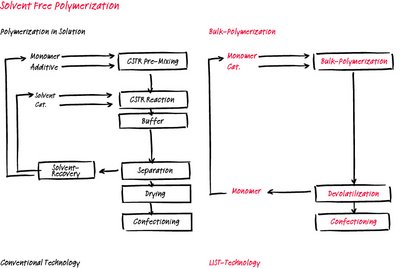

The processing industry faces mounting pressure to move toward process intensification, cleaner production, and continuous optimization. Meanwhile, environmental concerns continue to push operators to find ways to reduce consumption of raw materials and energy, eliminate toxic substances, and lower emissions and waste.

The LIST KneaderReactor Technology plays a central role in helping processors achieve these goals. Our vast expertise in chemical-, process- and mechanical engineering combined with our pronounced knowledge of the capabilities of LIST systems provide a unique toolbox for developing new innovative and economical processes.

LIST’s ability to run processes in the highly concentrated phase with little or no solvent is helping customers meet surging demand while reducing costs. With LIST, the ultimate goal of lowering both capital investment and operating costs while improving product quality and process reliability is possible.

Your Benefits

- Effective self-cleaning to minimize dead zones, product accumulation and product degradation

- Excellent kneading and mixing for better homogenization

- Low shear processing

- Effective heat transfer

High surface renewal efficiency - Large free vapour volume

- Precise and uniform temperature control due to large heat transfer areas

- Continuous processing

- Processing of sticky and highly viscous products

- Wide and flexible range of average residence times

- Wide range of possible residence time distributions (backmixed)

- Reliable process scale-up from pilot to industrial units

- High conversion rates

- Polydispersity Index 2…2.5

- Reaction at almost stoichiometric conditions

Downloads

| Title | Description | Language | Year | Download |

|---|---|---|---|---|

| Reactor for solvent-free polymer processing | Converting the polymer industry to solvent-free polymerisation processes and avoiding unnecessary recirculation decreases energy consumption and reduces waste production. This can be achieved with the horizontal large-volume Kneader Reactor with superior mixing and homogenisation performance. The casing, shafts and mixing elements are indirectly heated by heat transfer fluids and dynamically self-cleaning. | English | 2012 | |

| Ganz ohne Lösungsmittel – Syntheseverfahren in der konzentrierten Phase | Mit lösemittelfreier Prozessführung, dem sogenannten Dry Processing, lassen sich zwei entscheidende Ziele erreichen: umweltfreundliche Prozesse und eine deutliche Senkung der Investitions- und Betriebskosten. Die Schweizer Firma List konzentriert sich dabei nicht auf einzelne Verfahrensschritte, sondern auf den Prozess als Einheit, um eine ganzheitliche verfahrenstechnische und wirtschaftliche Optimierung zu erreichen. | Deutsch | 2009 | |

| Es geht auch ohne Lösungsmittel | Sie suchen ein lösungsmittelfreies, sicheres, umweltfreundliches und energieeffizientes Herstellungsverfahren, das neue Produkttypen mit neuen Qualitätsmerkmalen hervorbringt? Eine neue Technologie macht’s möglich. | Deutsch | 2009 | |

| Saying goodbye to solvents | Are you looking for a solvent-free, safe, eco-friendly and energy-efficient way of producing new types of products with new levels of quality? New technology is available to help you do exactly that. | English | 2009 | |

| Prediction of Kneader Reactor Bulk Co-Polymerization Continuous Processes | Batch trials were performed on a kneader reactor where a bulk co-polymerization was carried out. Polymerization conversion, viscosity build, reaction kinetics, and heat transfer calculations were performed using the experimental data from the batch trials. A continuous process was proposed for this bulk copolymerization and the models and results from the batch trials were used in designing the continuous process. Predictions of the continuous process using the batch trial data are compared to the actual continuous process, with a focus on polymer conversion, heat transfer, and torque prediction. | English | 2007 | |

| Bulk Polymerisation or Copolymerisation in a Novel Continuous Kneader Reactor | A new type of kneader reactor is proposed for the continuous radical (co-) polymerisation without solvent, based on the proven design of mature (kneader-) dryer technology. The reactor has been developed to satisfy all major aspects required for (co-) polymerisation while maintaining the safety and reliability of the previous mechanical design. The new kneader reactor offers a perfect combination of surface renewal and evaporative cooling to control temperature to high conversion (85 to 95%), even for bulk systems that have a strong gel effect (Trommsdorff’s effect) and high exothermicity. | English | 2006 | |

| Bulk polymerisation of MMA in a kneader reactor | The bulk free radical polymerization of methyl methacrylate (MMA) or the bulk free radical copolymerization of MMA based monomer recipes face a gel effect (Trommsdorff’s effect) and exothermicity. The kneader reactor offers a perfect combination of surface renewal and evaporative cooling to control temperature at high conversion (85 to 95%). | English | 2006 | |

| Continous polymerisation | Various types of reactor have been developed to date for improving the stability of the polymerisation process. This review describes a few examples of heterogeneous and homogeneous polymerisation, focusing particularly on viscosity control and heat removal. The production of solid polymer granules directly in a kneader-reactor with evaporative cooling is one efficient and reliable polymerisation technology. | English | 2003 | |

| CKR for continous polymerisations producing solid granular polymers | A review of the existing polymerisation processes is proposed, with particular attention to the control of viscosity and heat removal. Up to the present time, different types of reactor have been developed in order to improve the stability of the polymerisation process. A review of these reactors is presented for the heterogeneous and homogeneous polymerisations. The production of solid polymer granules directly in a kneader reactor under evaporative cooling is seen as an efficient and reliable polymerisation technology. | English | 2001 |